We look at product development differently

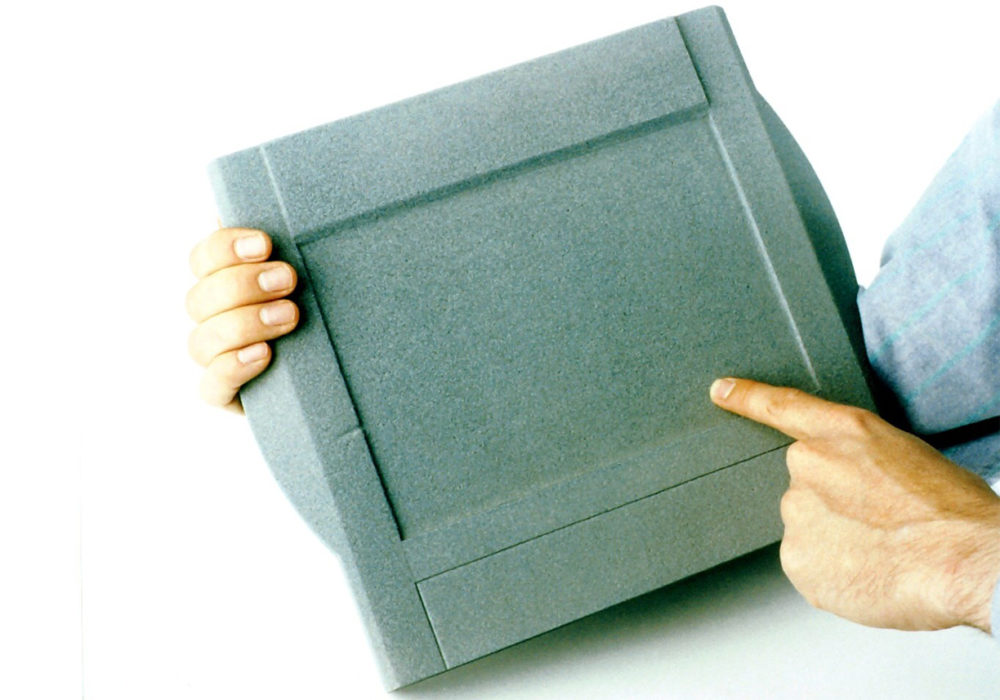

Evolve Design Solutions’ approach to product development is different. We believe that creating great products is an accomplishment, achieved through strategic partnerships with both clients and suppliers.

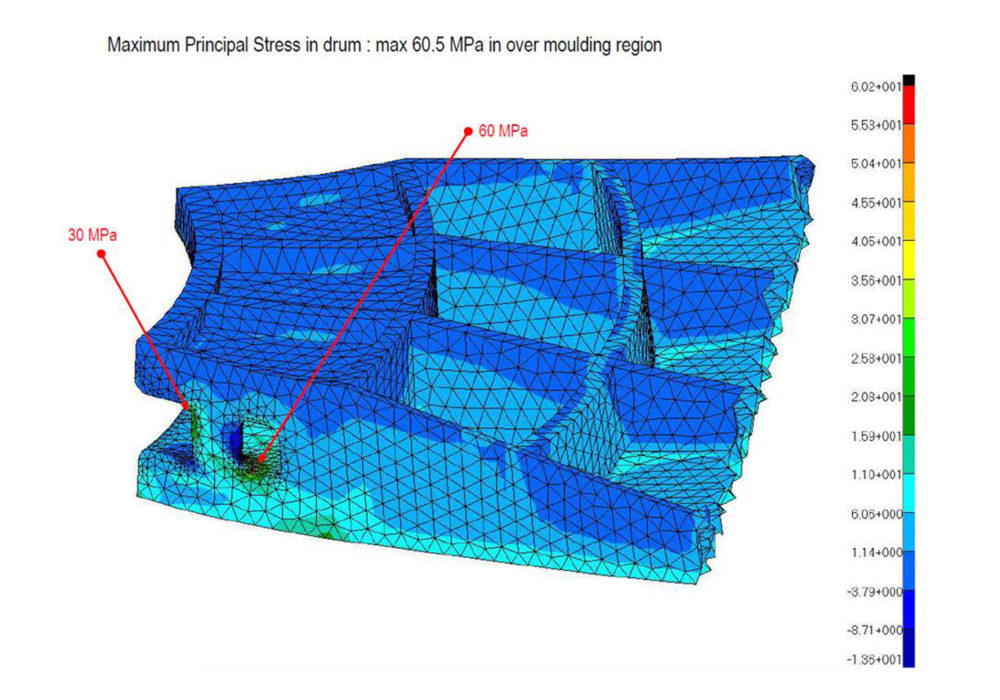

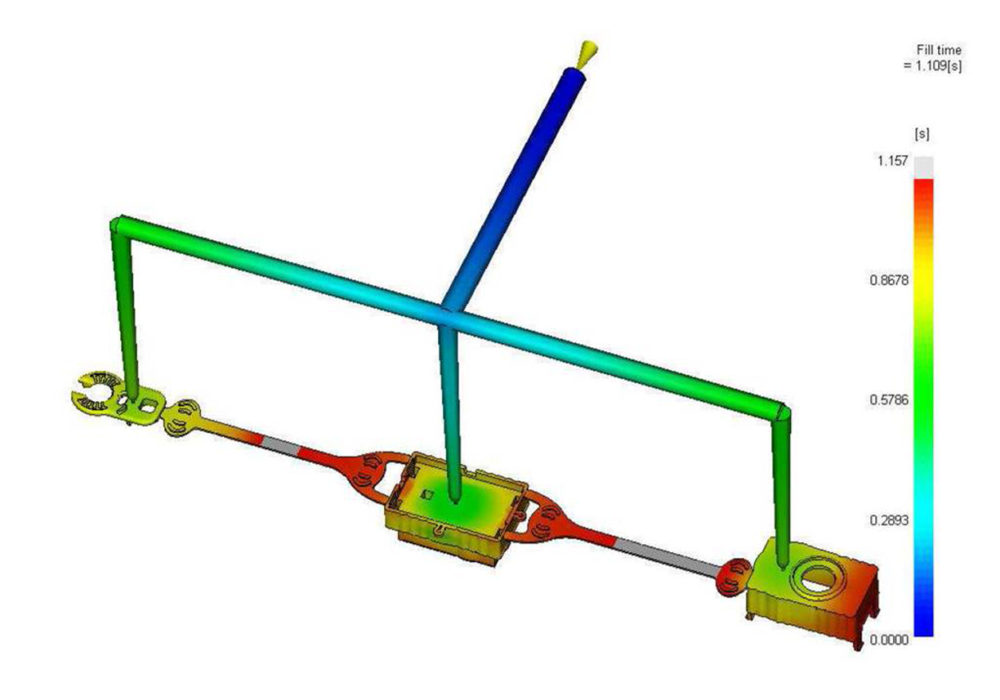

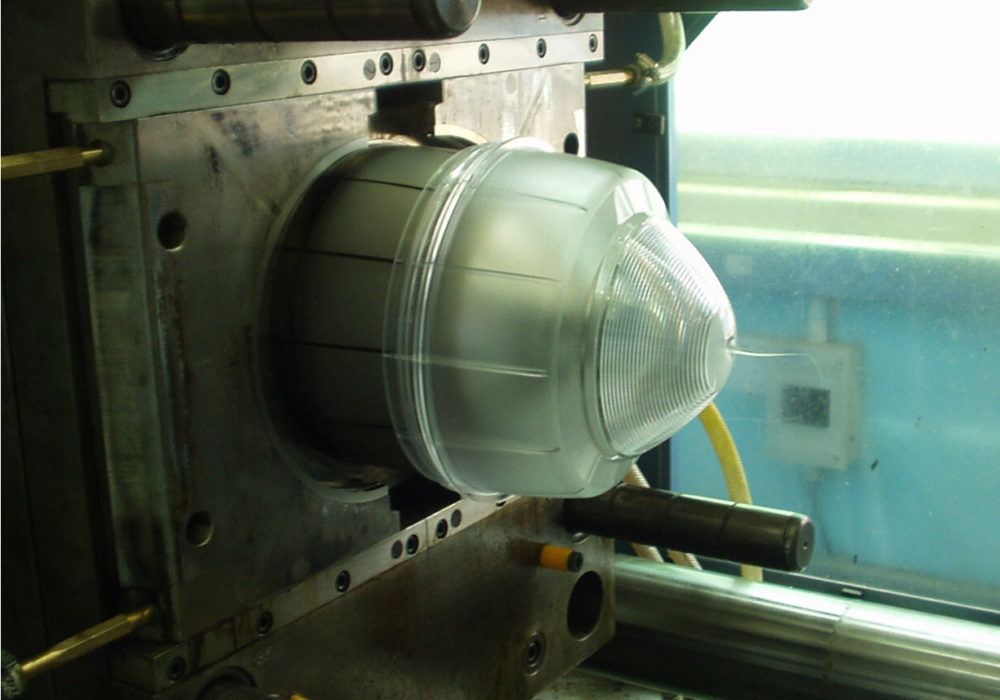

This collaborative process starts by looking at your vision of the project, and understanding the design challenges you face. We then draw upon the creative thinking, technical expertise, ability to combine form with function and the vast resources of our strategic partners, who are as committed as we are to your new product development project.

Treating product development as a partnerships program is a unique approach. It’s what sets apart Evolve Design Solutions, our created new products and our clients from the competition.

“Combining world-class product development services with the power

of strategic partnerships”